Why effective battery recycling will soon be required, and why future-proof battery designs should be the main priority

Not only is the battery market one of the biggest in the world, but it is also the one with the biggest growth potential. In 2020, there were 185GWh of batteries available globally. Many reliable sources predict that the market would grow tenfold in less than a decade. A CAGR of almost 27% is projected for the years 2020 to 2030, resulting in a market volume of 2035 GWh for batteries by that time.

However, the recently disclosed data by SNE Research, which rated the overall market volume to 296,62GWh in 2021, which is almost 6% above the predicted demand in 2021, tends to make these numbers look too conversational.

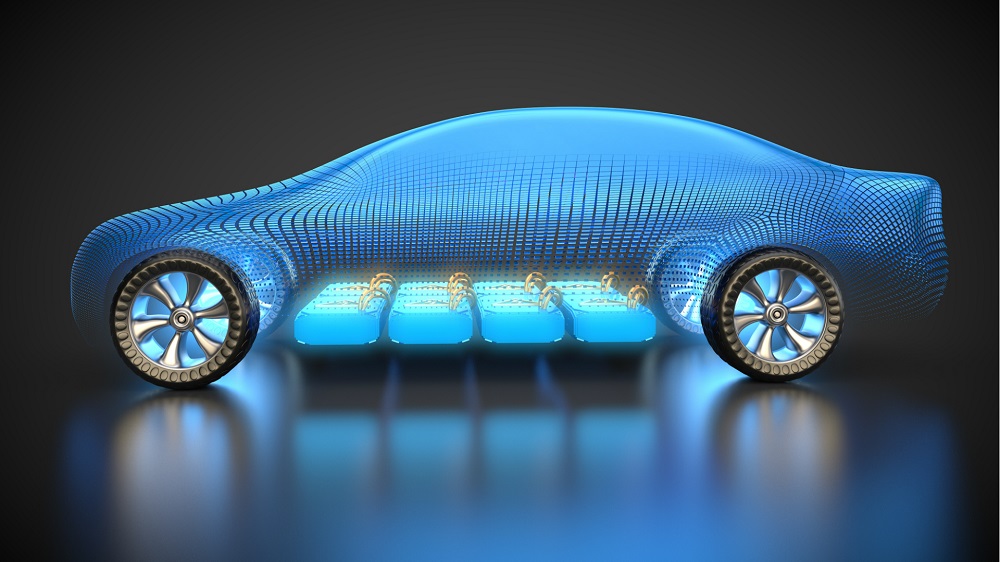

The primary engine for the anticipated expansion is the transportation sector, which also includes the vital EV passenger car market. When commercial EVs are included, the demand for batteries is projected to increase from 100GWh in 2020 to over 1700GWh in 2030. The large growth in demand puts a lot of strain on battery suppliers, who must quickly expand their capacity to produce affordable traction batteries, particularly in Europe.

Since EVs require charging, the overall energy demand will rise sharply as the number of EVs increases. Peak shaving or buffer energy storage systems will also be required to sustain the grid in conjunction with this, particularly for fast charging stations (stationary as in the above chart).

Lithium and other basic minerals will soon have more demand than supply.

Because of the current raw material shortage, Li-Ion battery prices have already surged. Although the price of lithium is known to fluctuate, there appears to be a trend toward an increasing price per ton.

We can expect the price not to decrease as the demand remains high and begins to exceed the supply capacity. This problem becomes real between 2023 and 2027

The secret to success in the near future will be to greatly step up recycling activities in order to reclaim the valuable raw materials and reduce reliance on Chinese raw material suppliers. Global automakers like Volkswagen are already dealing with this issue and, in part because of EU restrictions, aim to recover 95% of the raw materials from their batteries. Almost every major worldwide automaker and battery (cell) supplier is currently seen making significant expenditures in recycling facilities and processes.

In the recycling process, achieving a high raw material recovery rate requires avoiding contamination. The ideal solution is to recycle individual battery pack cells. Due to the welded and/or bonded battery packs, disassembling the battery will be expensive and inefficient compared to purchasing fresh raw materials. It will be necessary to concentrate on sustainable technology with second life capabilities, effective recycling options, minimized disassembly costs, and an appealing total cost of ownership in order to have a battery that is future-proof.

Taking into account the Total Cost of Ownership (TCO) in order to increase the appeal of sustainable batteries

A battery system accounts for about 40% of the production expenses of a battery electric vehicle (BEV). Thus, the competition was to maintain the lowest feasible battery purchase price (i.e., production price). However, you must include more than just the purchase price in your computation if you take the total cost of ownership into account.

In order to make a battery “2nd life ready,” more application scenarios than simply the vehicle’s first life should be taken into account during the development process. To provide the most flexibility for second life applications, optional packaging technology that is sustainable and simple to assemble and disassemble will be employed. This packaging can be set up at the cell level, allowing for cell refurbishment to prolong the battery’s lifespan. Our requirement for electricity is increasing rapidly due to the significant rise in BEV and PHEV usage, necessitating grid improvements.

Selecting the appropriate battery cell must be done at the very beginning of development. Only one form factor—the cylindrical, pouch, and prismatic cells—can be selected, and that one will also be the winner in the subsequent second life, given their respective benefits. Because they are industrially standardized and have a wide range of applications in which they may be placed, cylindrical cells like 18650 and 21700 are predestined for a sustainable use.

When the local power supply is insufficient for simultaneous charging, peak shaving and buffer energy storage solutions may be required for rapid charging stations. Due to the varying electrical, regulatory, and safety requirements of those stationary energy storage devices, modifications for second-life BEV/PHEV batteries may be necessary.

It should thus be taken into consideration during development that at least a basic adaption for second life is achievable in order to maintain the TCO low. When considering the total cost of ownership (TCO) and the profit from the second life, this may lead to a higher purchase and/or production price for the battery.

A question about cutting-edge battery packing with an emphasis on sustainability

By producing heat and power from renewable sources, energy supply may be made climate-compatible and independent of imports of raw materials. Energy storage systems that are effective, resource-efficient, and kind to the environment are especially necessary when using variable renewable energy sources like solar and wind power.

That’s precisely when the cutting-edge e.quikk technology from E-Stream comes into play. The individually extracted and unharmed removal of each battery cell from the battery pack is made possible by the specifically designed and patented packaging approach for the electrical and mechanical connection of battery cells using special multilayer printed circuit boards. This makes it possible to upgrade E-Stream battery systems, much like a software update. During this procedure, the outdated battery cells are taken out of the storage systems and restored. This preserves energy and raw material resources by greatly extending the service life of the E-Stream energy storage systems’ system components.

Used battery cells that no longer fit the specifications of some goods can be removed without causing damage, allowing them to function independently from their first life application and for years in lower power applications. Utilizing second-life cells is highly significant from a strategic, financial, and environmental standpoint because battery cells include important metals like copper, nickel, manganese, cobalt, and essential raw materials like lithium and natural graphite. Apart from its numerous technical benefits, e.quikk technology is distinguished by its reversible and non-destructive procedure of disassembling battery storage devices.

The recycling process of E-Stream battery systems can yield significant time, cost, and energy savings due to the significantly simplified separation of raw materials. This opens the door for a practical and efficient circular economy.

Source:

https://battery-news.de/wp-content/uploads/2022/02/220303_Batteryprojects_February-11.png

https://www.greencarreports.com/news/1131521_vw-to-recover-95-of-ev-batteries-raw-materials

https://ec.europa.eu/commission/presscorner/detail/en/qanda_20_2311

https://battery-news.de/index.php/category/batterierecycling/ https://www.beuc.eu/publications/beuc-x-2021-039_electric_cars_calculating_the_total_cost_of_ownership_for_consumers.pdf

Bạn cần đăng nhập để tương tác với nội dung này: Đăng nhập.